Services

Comprehensive MRO Support Backed by Industry-Leading

Operational Experience

NDT inspections, metal and composite structural repair and component upgrades developed from the lineage of Nextant Aerospace. Whether addressing damage or extending the life of airframes and components, we ensure your aircraft performs safely and reliably.

Aircraft Services

Component Repair and Overhaul, Engineering and Certification, NDT and Parts/STC Kitting.

Non-Destructive Testing

Flexjet Technical Services provides expert inspection services using eddy current, ultrasonic, magnetic particle and liquid penetrant non-destructive testing methods. Our NDT inspections strictly adhere to manufacturer requirements, industry standards and all applicable ASTM, API, ASME, AWS and SAE specifications. All inspection services are available at your facility or our NDT Laboratory. Certified level 2 & 3, Cessna approved NDI facility No. C-296, TCM 6-cylinder engine crankshaft UT authorized, AWS QC-1 certified welding inspector, NDT methods include ET, UT, MT, PT, RT, and VT.

Methods

Eddy Current

Surface scan, bolt hole, conductivity, nonconductive coating measurement and WeldScan®.

Magnetic Particle

Wet, fluorescent, horizontal FWDC bench and wet or dry portable yoke.

Ultrasonic

Longitudinal & shear wave flaw detection and thickness gauging.

Liquid Penetrant

Fluorescent and visible penetrant testing in method “A” and “C” removal techniques.

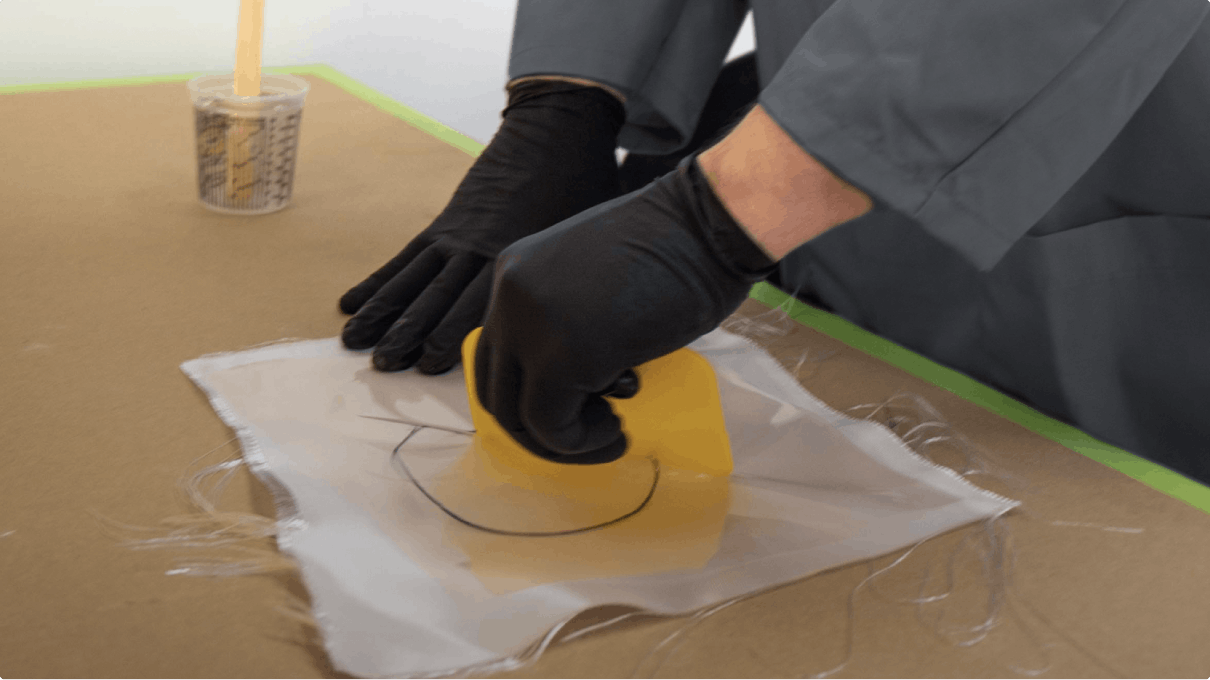

Composites

Material bond test and core damage capable.

Certifications

Certified Level 2 & 3

In accordance with ASNT’s SNT-TC-1A and CP-189 documents, NAS-410 and ATA-105

TCM 6-cylinder Engine Crankshaft UT Authorized

Cessna Approved NDI Facility

AWS QC-1 Certified Welding Inspection with D1.1 Endorsement

Level 1, 2 and 3 Training/Education Services

Aircraft Composite Repairs

Innovation and Technology in the World of Composites

With remote or in-house support, our technicians can repair, overhaul and finish/paint all sheet metal and bond composites with precision. Repairs are performed on-wing or sent to our facility. Certified technicians overhaul and finish fairings, flight controls, structural components and more. Qualified in solid laminate, honeycomb, Kevlar, carbon fiber, fiberglass – both dry and pre-impregnated -- aluminum and CRES bonding.

Structural Repairs

Efficiency and Expertise

Structural components of all material types are repaired and overhauled in-house at our facilities, with sheet metal fabrication, intricate work and capabilities that surpass expectations. From control repair to required fixtures and more, the sheet metal department can fabricate nearly every bracket, skin or frame that is made out of metal – even parts that are not available on the market – reducing your costs and accelerating your return to service.

Government

Flexjet Technical Services has earned the trust of both the US Military and US Government via several USAF, USN and government contracts in both the primary and sub-contractor roles. We serve our US Military, Law Enforcement Agencies and FAA across various programs. We have proven and continue to prove that we offer the highest level of service, quality and performance within the aviation MRO space.

Our numerous awarded US Government contracts are a testament to the level of trust evident in the highly demanding and mission-critical defense and law enforcement arena between Flexjet Global Maintenance Product & Services and our customers. We actively support CL-601, CL-604, T-1A, T-6, C-26, C-23, G-V and Citation Encore for various agencies and departments of the US Government.

USAF T-1A PL-21 Cockpit Modernization

AMARG T-1A Support Equipment

USAF T-1A CLS/COMBS

T-6 Component Repair

FAA Challenger Paint and Corrosion Repair

FAA Challenger ADS-B Out

USN C-26 PL-21 STC Amendment and Avionics Install

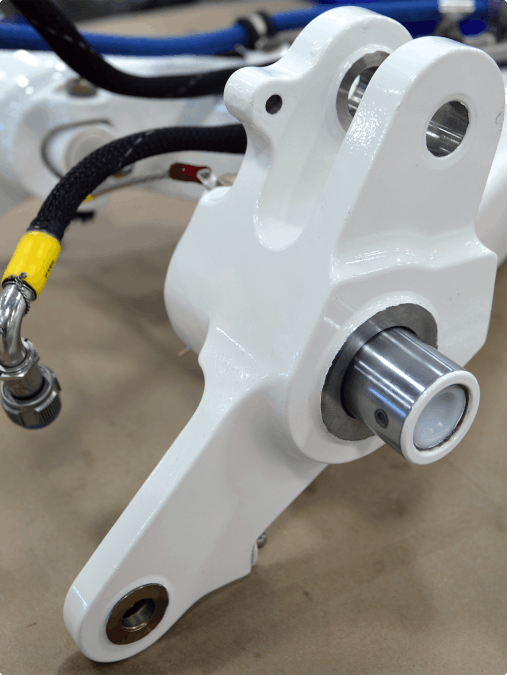

Landing Gear Repair & Overhaul

Flexjet Technical Services leverages extensive experience and proven processes to serve as an industry-leading landing gear solution.

Repair

Overhaul

Aircraft/Airframes

Paint

Cadmium Plating

Certificates

The Federal Aviation Administration (FAA) requires accurate and current documentation to ensure the work being performed on your aircraft complies with the FAA’s regulations and specifications. With our long-standing relationship with the FAA and meticulous attention to detail, we provide our customers with all necessary documentation.

Operations Specifications

Repair Stations Certificate

General Liability Certificate

EASA Certificate

Mexico AFAC Certificate

Brazil ANAC Certificate

Experience Meticulous Attention To Detail And Minimum Downtime

Experts you can count on for everything from major repairs to overhauls and completions